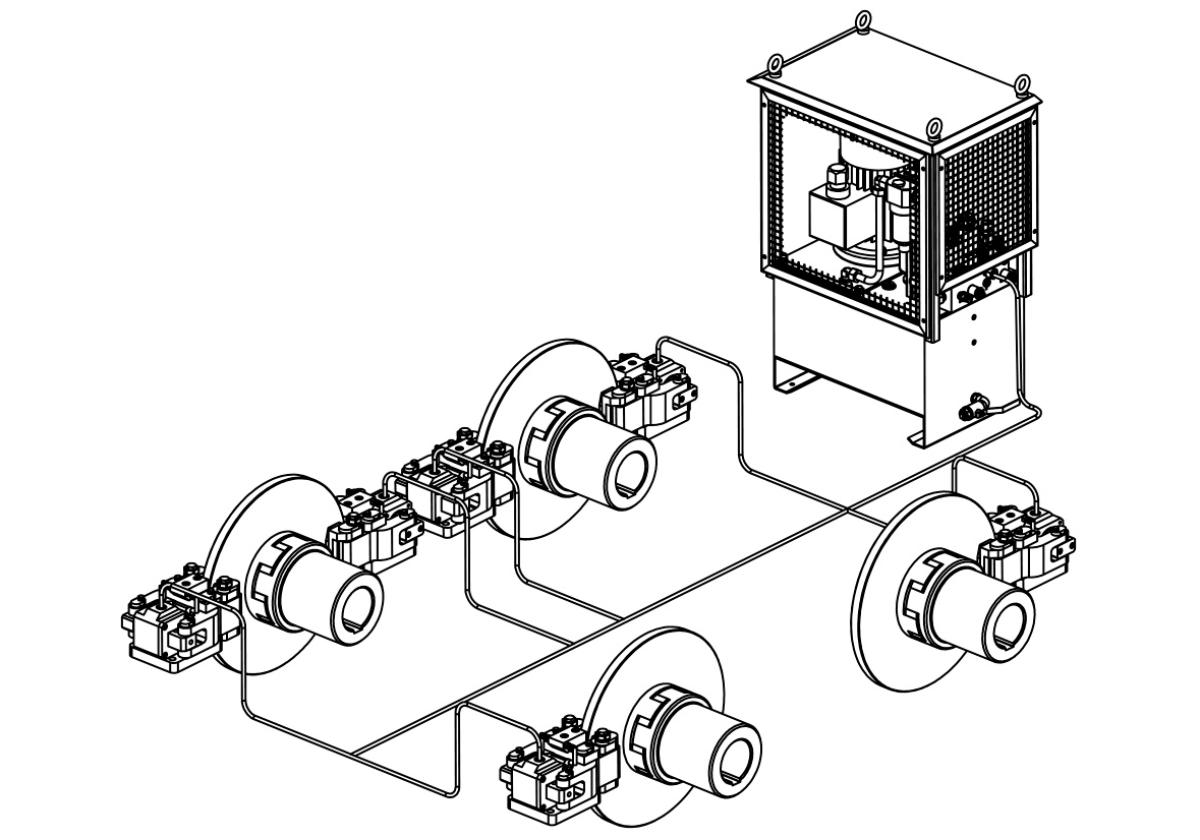

The ZHT-1 disc brake system consists of a hydraulic aggregate and several ZH-1 brake calipers connected to it. It is mainly used in belt conveyor drive systems. The springs mounted in the calipers cause the calipers to clamp on the brake disc and the supply of pressurised oil from the aggregate causes the calipers to spread apart and allow the brake disc to rotate freely. The use of a single hydraulic aggregate supplying several calipers enables their braking process to be controlled simultaneously. Depending on the version of the aggregate, single-stage fast or smooth braking or 2-stage braking with the possibility of setting the threshold between stages and the possibility of setting (by supplying voltage to the relevant solenoid valve) the starting moment of the 2nd braking stage is possible. The calipers may be equipped with a brake release sensor and a lining wear sensor to indicate when the caliper needs to be adjusted or when the minimum thickness of the friction lining is reached, to indicate when it needs to be replaced. The aggregate can also be equipped with a threshold pressure sensor indicating that the pressure value set on the sensor has been reached or exceeded (which can also be used indirectly as information about the release of the calipers).