The braking force of the clamp is induced by the force of springs built into the hydraulic cylinder, which presses the brake shoes against the side surfaces of the rail heads through the arms. Voltage activation starts the motor and the hydraulic power pack pump, increasing the oil pressure in the cylinder and causing the piston to move and compress the springs, simultaneously spreading the arms and allowing the movement of the machine. In the event of a loss of voltage, the power supply is switched off and the shoes clamp on the rail. The system consists of a clamp with a release indicator, a hydraulic power pack and an electrical cabinet that controls the power pack so that the required hydraulic pressure is maintained in the cylinder to ensure that the clamp is released without the need for continuous operation of the electric motor and pump in the power pack.

The power pack operating and emergency status is indicated by lights on the control cabinet. The power pack can be additionally equipped with a heater to allow operation at low temperatures.

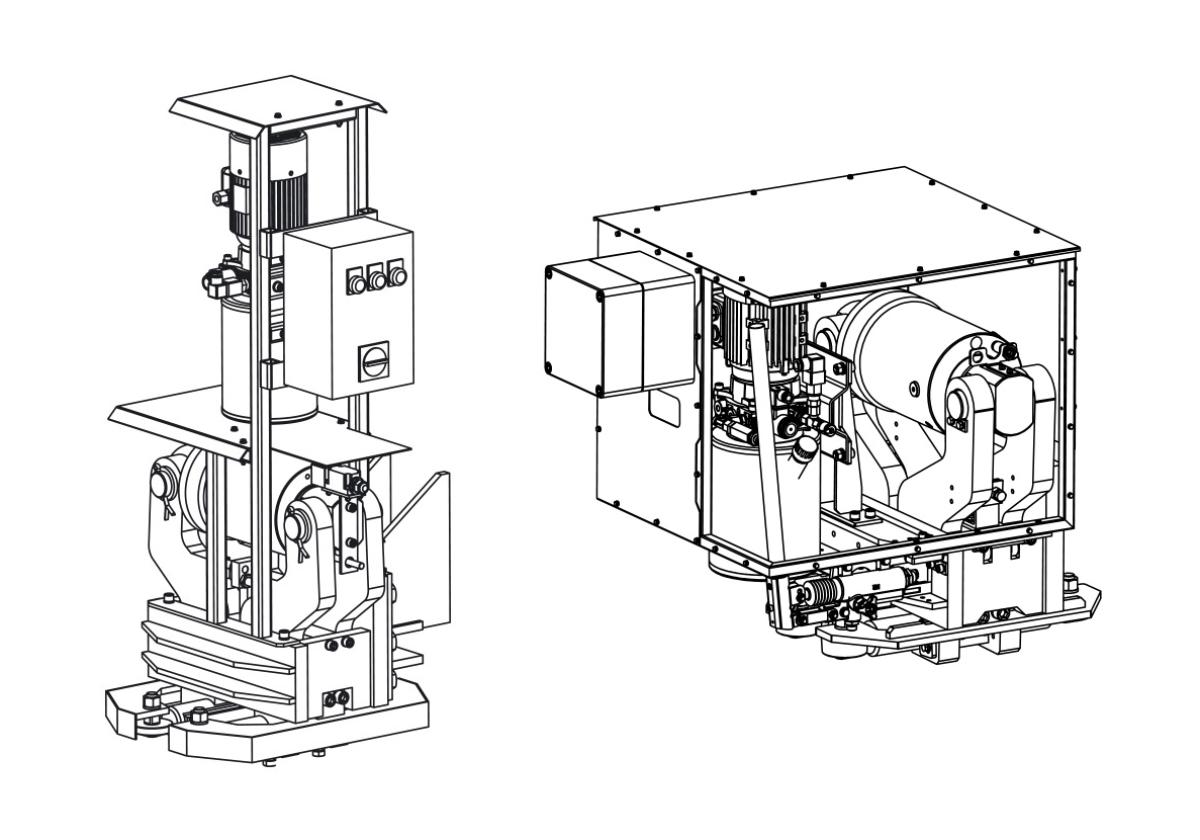

The assembly can be placed on a single structure or the clamp can be mounted separately, while the power pack with the control cabinet is mounted on a separate structure and connected by wires.

It can also be supplied with a connection cabinet only (power pack control system to be provided by the user).

The clamp can be equipped with manual hydraulic pump for emergency brake release.

- braking force up to 100 kN (different braking force possible).