Natural rubber WingLock™ element (1)

- Finite-Element optimized flexible design, featuring WingLock technology

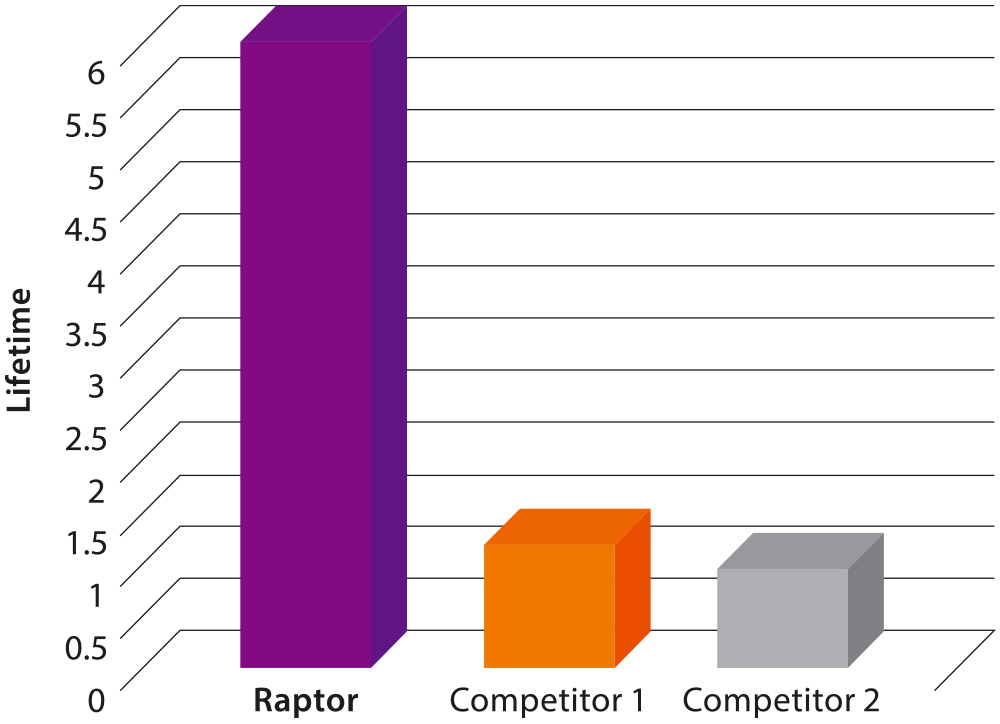

- Higher bond strength, improved fatigue resistance, and documented longer life

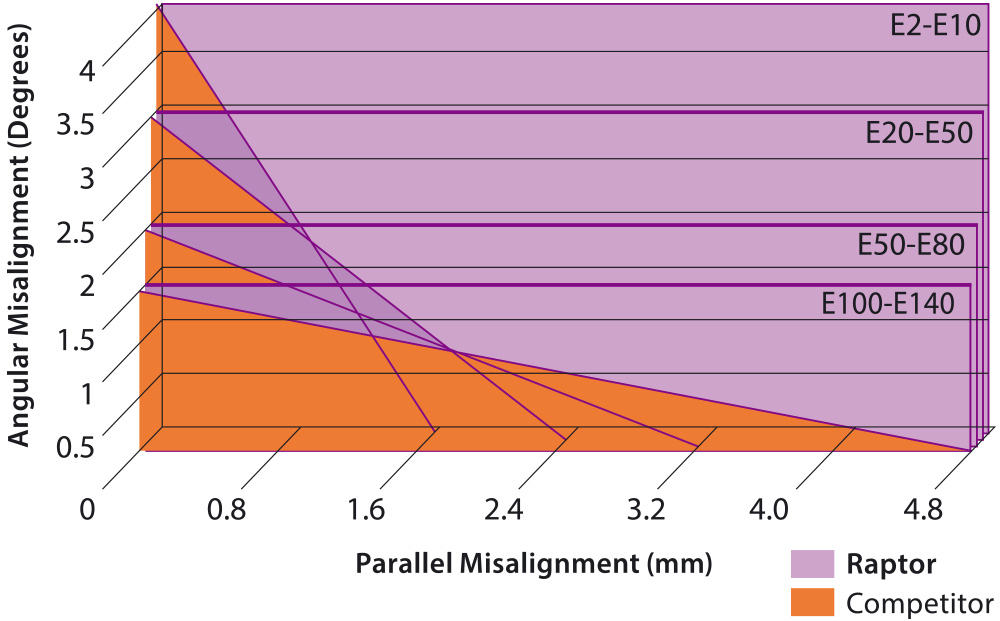

- Industry leading misalignment capabilities

- Torque range up to 38.438 Nm

Easier installation & reduced maintenance (2)

- Slotted clamp ring holes offer 187% more hardware clearance

- Split element for easy replacement

- Drop-in interchange without any modifications or additional materials

- Maintenance free element

Longer driven equipment life (3)

- Rigorously tested to 10x DIN 741 coupling standards

- Significantly lower torsional and bending stiffness

- Up to 16.7x increase in connected L10 bearing life

- ISO class 10.9 hardware offers a 40% increase in proof strength

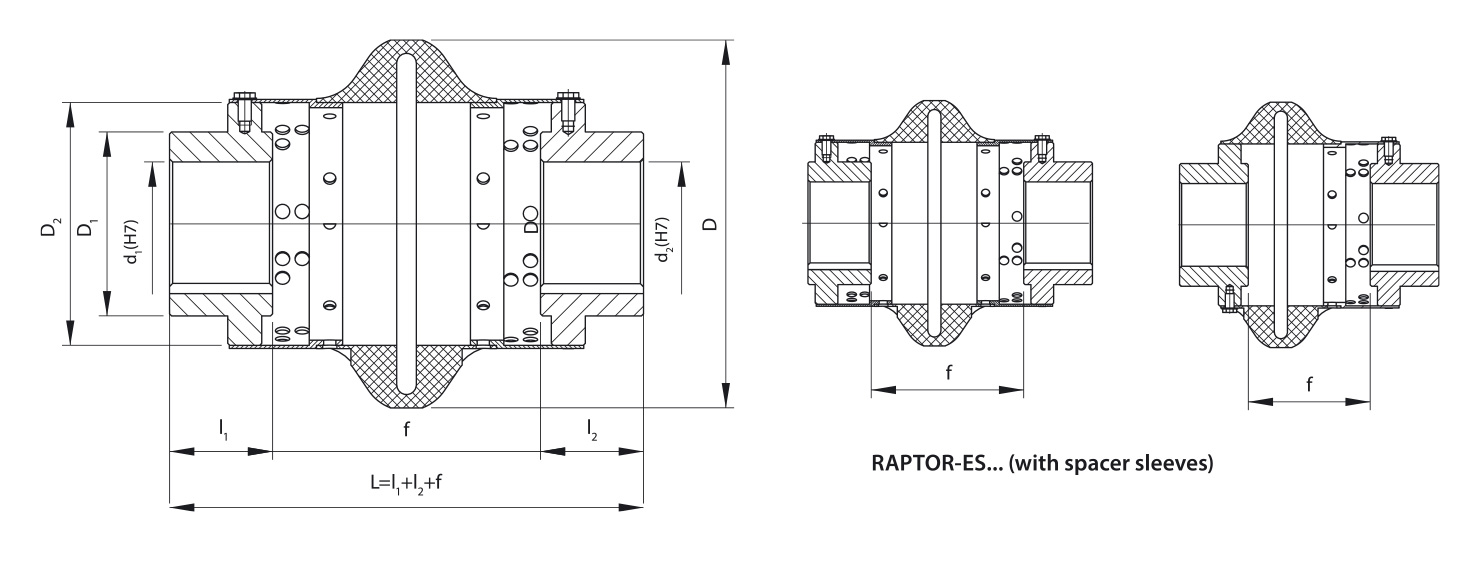

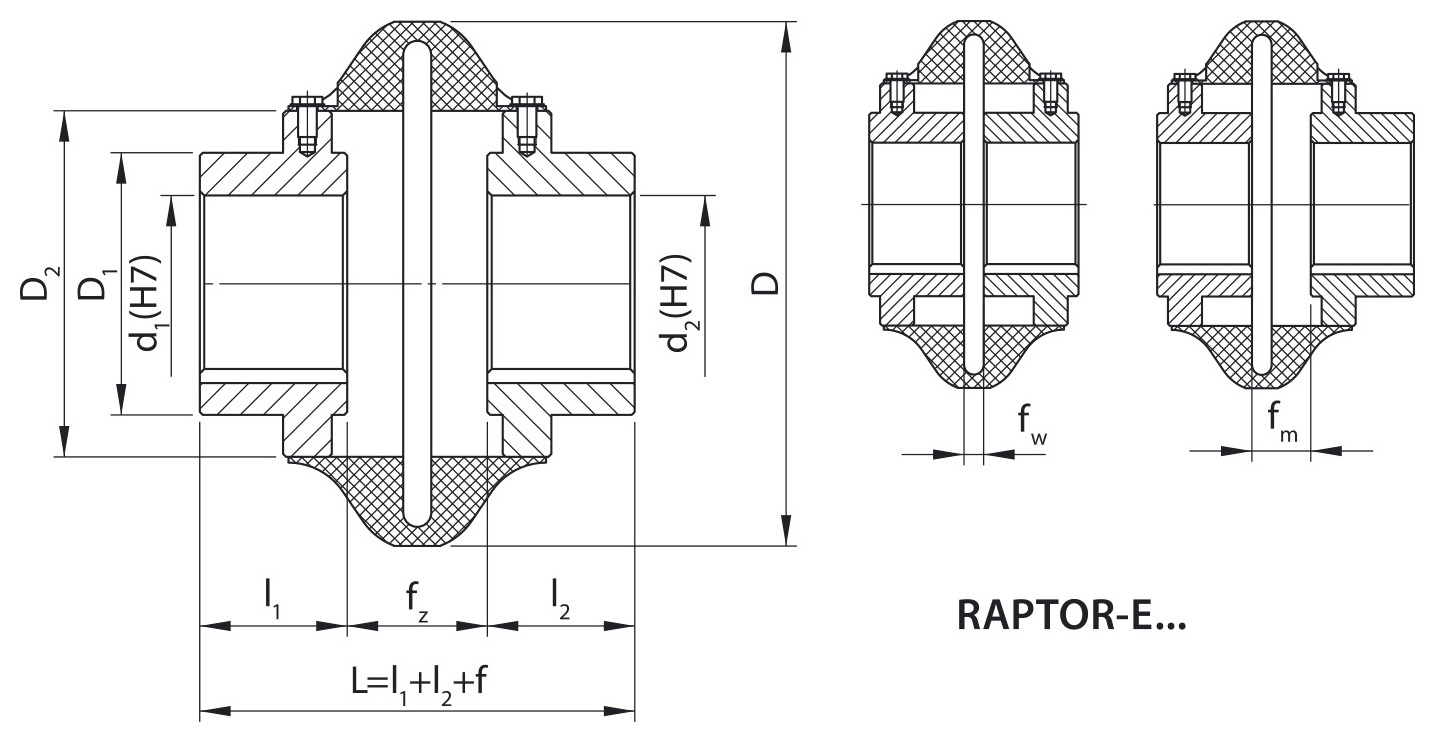

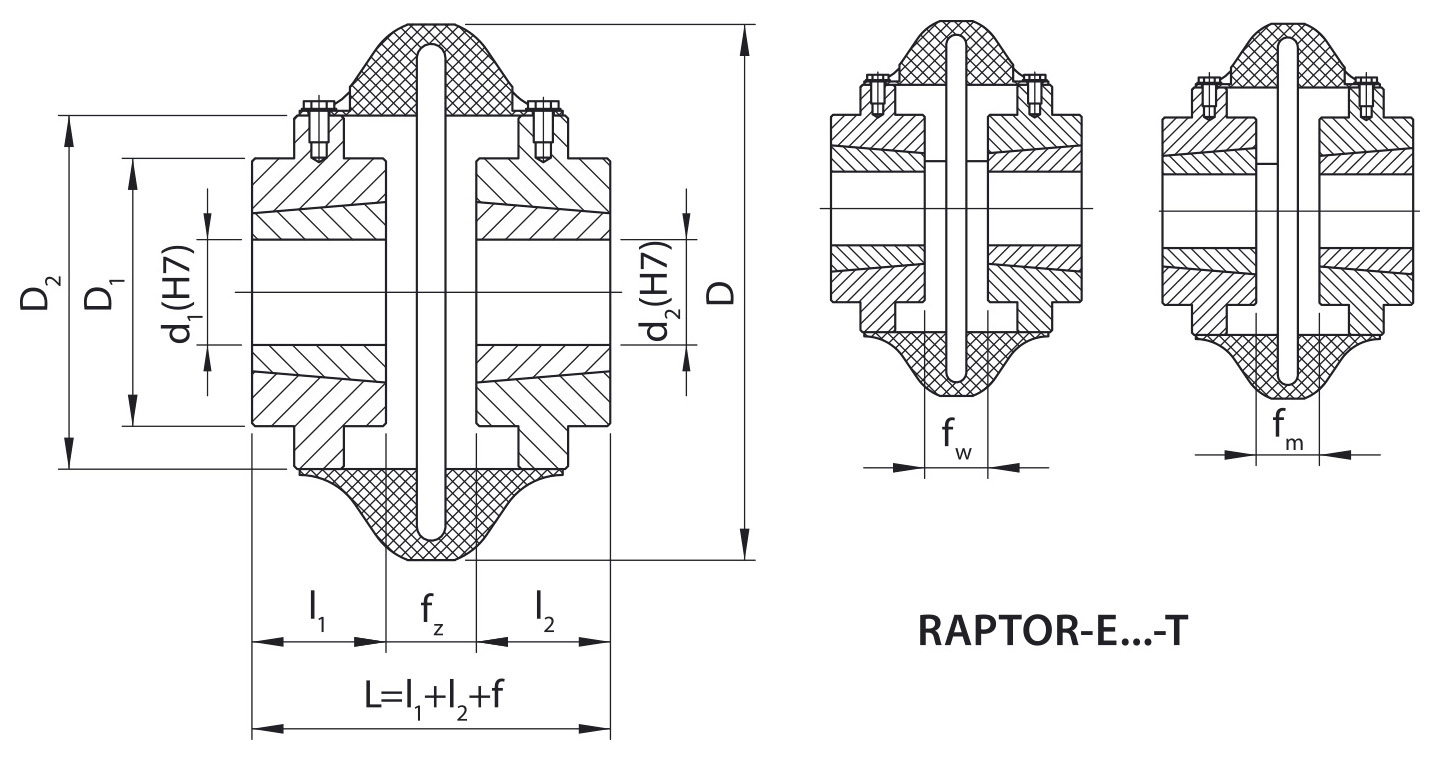

Flexible mounting options (4)

- Close-coupled and spacer designs for a wide range of shaft gaps

- Interchangeable hubs for reduced inventory

- Finished bore hubs with setscrew locking for easy installation

- Taper-Lock bushed hubs for clean, compact installation

- Bores up to 220 mm

Documented performance

Results based on accelerated life testing at 1.5× catalogued torque, while subject to 4° angularmisalignment and 4.8 mm parallel misalignment.

Industry leading misalignment capabilities

Easy as 1-2-3

Installing Dodge Raptor couplings is quick and easy. The Raptor’s horizontally split element doesn’t require locking shafts during installation, meaning a faster installation that requires fewer tools and eliminates shaft damage. Simply fasten the shaft hubs, install the element, and tighten the hardware.

Example of designation of the RAPTOR coupling with the nominal torque of Mn=261 Nm, hub holes diameters of d1=38 mm, d2=42 mm, hub holes lengths of l1=l2=52 mm, size of E20, without spacer sleeves:

261-38/52-42/52 – RAPTOR E20 Flexible coupling

Example of designation of the RAPTOR coupling with the nominal torque of Mn=261 Nm, hub holes diameters of d1=38 mm, d2=42 mm, hub holes lengths of l1=l2= 52 mm, size of E20, with two spacer sleeves:

261-38/52-42/52 – RAPTOR ES20-2 Flexible coupling