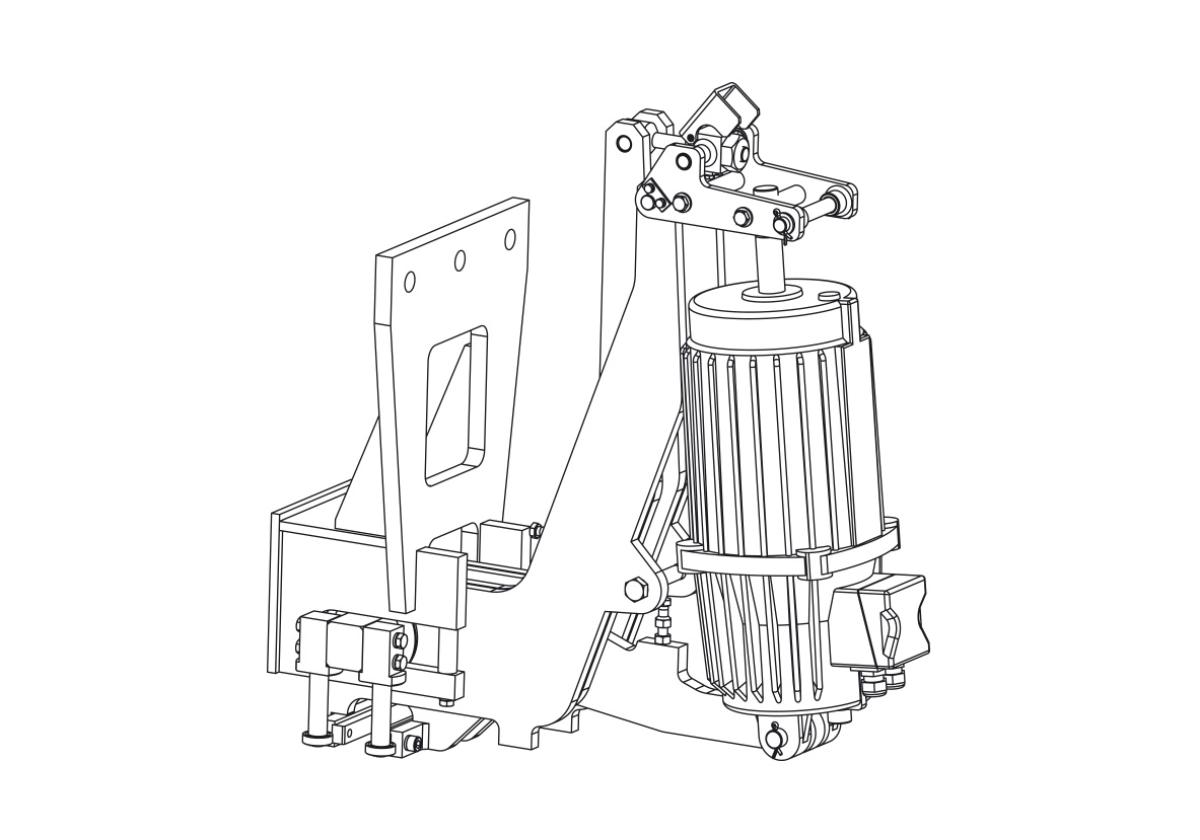

The AHS clamps are designed to be installed on conveyor belt throw-off carriages where the existing structure does not allow a face-mounted installation in the running rail axis.

The braking force (clamping of the shoes on the running rail) is mechanically induced by a spring integrated in the body of the release mechanism. Release of the clamp (spreading of the brake shoes) occurs once the release mechanism has been energised, causing the pump that pumps oil into a chamber located under the release mechanism piston to be switched on. This results in an upward movement of the piston and the brake arms and shoes are moved away from the head of the rail by an articulated lever system, which allows unobstructed movement of the machine. If the voltage supply to the release mechanism is interrupted, the spring in the release immediately moves the piston downwards automatically and braking is performed by pressing the brake shoes against the side surfaces of the rail head.

The connection dimensions and fitting method can be adapted to suit the requirements of the installation.

- braking force up to 3.6÷ 8 kN (different braking force possible).